Ultrafine Grinding Mill for Dolomite Stone Micro Powder Grinding Mill Stone Grinding Mill Mtw European Mill

Basic Info

| Model NO. | MTW138 |

| Condition | New |

| Installation | Training, Technical Support, etc. |

| Certificate | ISO9001: 2000 |

| Warrenty | 1 Year |

| After-Sale Service | Training, Technical Support, etc. |

| Factory Visit | Most Welcomed |

| Mining Object | Petroleum Drilling and Production Equipment |

| Final Powder Size | 30-1000mesh |

| Input Size | <20mm |

| Capacity | 3-20tons Per Hour |

| Transport Package | International Packing Standard |

| Specification | ISO, CE, SGS |

| Trademark | TYM |

| Origin | China Mainland |

| HS Code | 8474201000 |

| Production Capacity | 36 Sets/Month |

Product Description

MTW series grinding mill called the European mill, which has a number of independent intellectual property rights, featured by small occupation area, low consumption, high yield, good appearance and environmental protection. So that it has been extensively used to grind and process materials in metallurgy, building materials and chemistry industries. European mill is widely applied to process non-inflammable and none-explosive materials with Mohs hardness less than 9.3 and humidity under 6%.

It is widely used for grinding materials in metallurgy, building materials, chemical industry, such as sand yard, concrete mixing station, dry mortar, power plant desulphurization, quartz sand production gravel yard, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand production and other industrial grinding projects.

[Input]40mm [Output]0.045-1.6mm [Capacity]3.5-25t/h

Features

1.Adopting bevel gear integral drive-system achieves small energy loss and high efficiency.2.Inner automatic Thin-Oil lubricating system, make the operation more convenient reliable.3.Arc air channel guarantees small loss of the air volume and good material flow.4.Cambered shovel with renewable edge.5.Streamlined design of classifier's top cabinet makes resistance greatly reduced.6. Higher powder grinding efficiency and lower cost.7.No resistance snail shell (small checking door so that there is not an eddy air flow)8.Output size is adjustable and controllable the powder selecting efficiency is higher than before.9. Roller device adopts linkage pressurization which is using the most advanced technology.

Work Principle

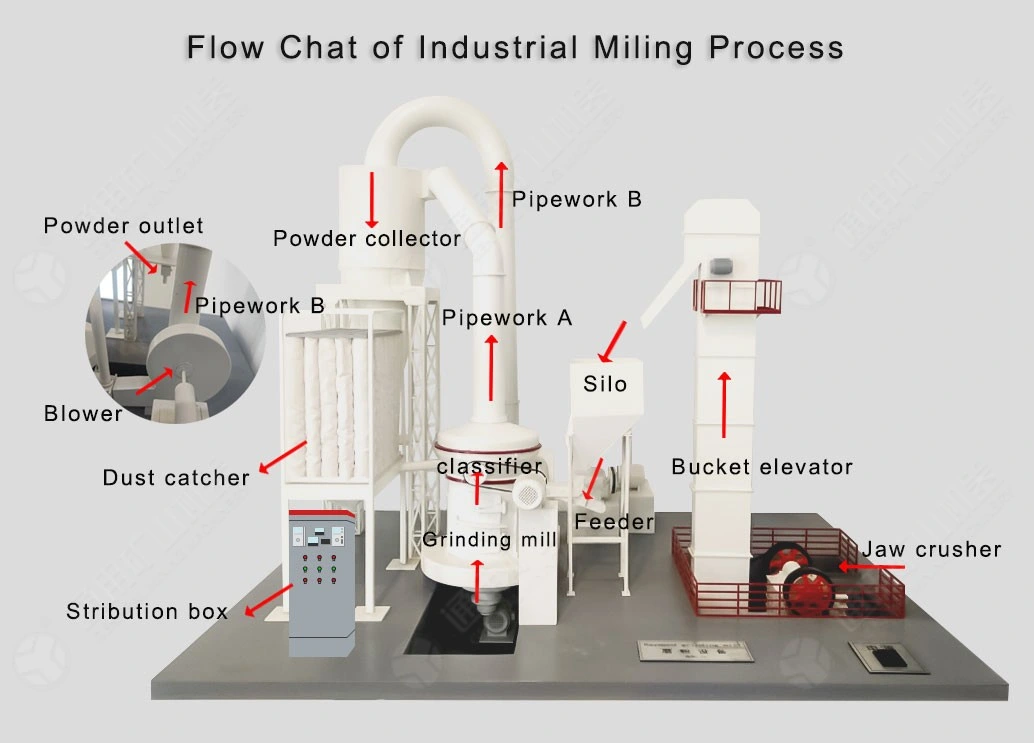

The whole set of equipment is mainly composed of main machine, powder separator, fan, jaw broken, bucket elevator, electromagnetic vibration feeder, storage bin, pulse dust collector, pipeline device, Cyclone Powder Collector, electric control cabinet, motor, etc. .

The working principle of the European version mill made by Zhengzhou General Mine Machine Co. , Ltd. is a vertical structure with small floor area and strong set, and the main drive device adopts an airtight gearbox, which makes the drive stable, it is more reliable, easier to maintain and more productive than the Ramon before the retrofit.

The working process of the main machine of European mill is that the central shaft is driven by the whole transmission device of bevel gears, the upper end of the shaft is connected with the roller hanger, and the roller device is installed on the hanger to form the swing fulcrum. The grinding roller device not only revolves around the central axis, but also revolves around the grinding ring. The grinding roller itself rotates due to friction. A spade is arranged under the hanger of the grinding roller, and the position of the Spade is at the lower end of the grinding roller. In the process of rotating the spade and the grinding roller together, the spade is thrown to feed the material to the grinding ring of the grinding roller, forming a cushion layer, the grinding roller of the material layer produces an outward centrifugal force (i. e. an extrusion force) to crush the material, thereby achieving the goal of pulverizing.

Product Parameters

| Model Specification Name | MTW110 | MTW138 | MTW178 | MTW215 | MTW1420 | MTW1720 |

| Quantity of roller (PCS) | 4 | 4 | 5 | 5 | 4 | 5 |

| Inner diameter of ring (mm) | 1100 | 1380 | 1750 | 2150 | 1420 | 1720 |

| Rotary speed of main frame(r/min) | 120 | 96 | 75 | 65 | 103 | 92 |

| Max.Feeding size(mm) | < 30 | < 35 | < 40 | <50 | <30 | <40 |

| Output size (mm) | 1.6-0.045 The Fineness is 0.038 | 1.6-0.045 The fineness is 0.038 | 1.6-0.045 The fineness is 0.038 | 1.6-0.055 The Fineness is 0.045 | 1.6-0.045 The Fineness is 0.038 | 1.6-0.045 The Fineness is 0.038 |

| Capacity (t/h) | 3.5-10 | 6.5-15 | 11-25 | 20-50 | 3-10.5 | 5-18 |

| Overall dimension (mm) | 8910×6950×9010 | 10920×9655×10227 | 12095×10023×9916 | 14500x11200x10400 | 10050x8335x9715 | 13390x7790x8410 |

| Total weight (t) | 18 | 28.5 | 46 | 96 | 90 | 160 |

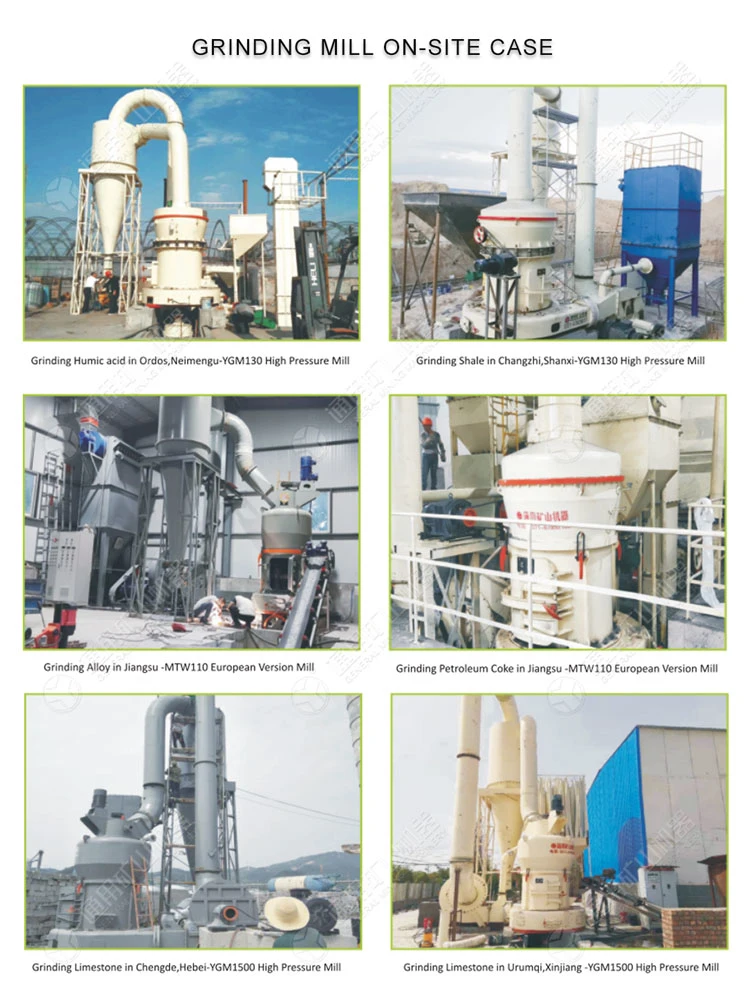

Customer site

The following is the work site of other customers, just for your reference. If you have the grinding mill or other mining machinery demands, please contact me with no hesitation.

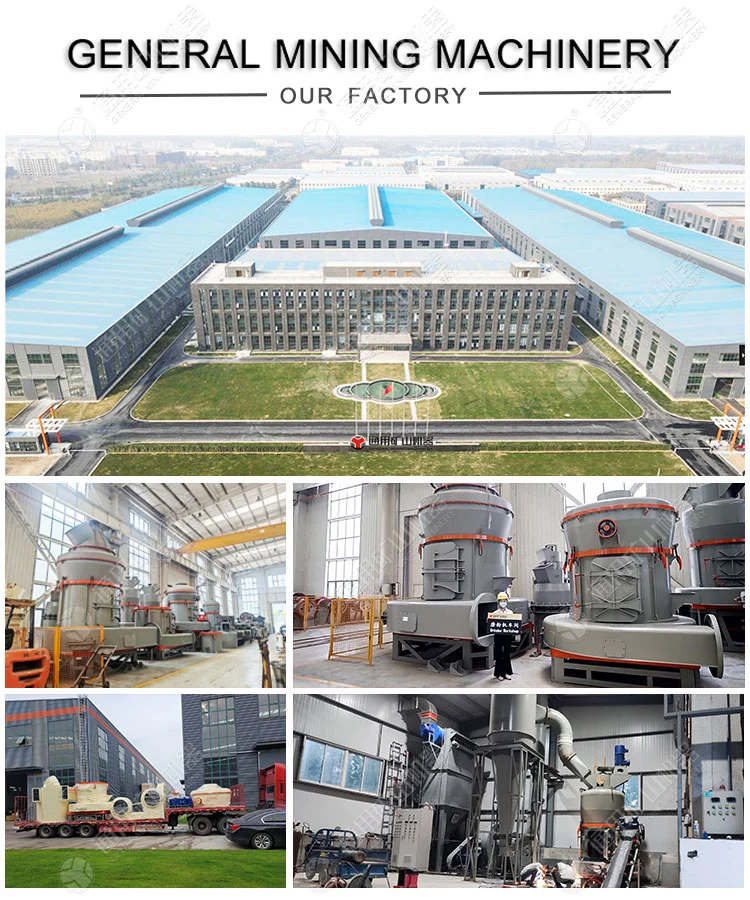

Company Profile

We hope our perfect products and service can satisfy you,and welcome to our factory to visit .Looking forward to building long-term relationship with you !

Packaging &services

Packing

Standard parts are packed in the wooden boxes, and the big parts are packed with plastic membrane.The whole machine is loaded in the container

Our services

Warranty 100% brand new when leaving the factory. The seller guarantee quality of the machines (excluding wearing parts) for a period of one year from the date of trial run finish under our technician's guidance, but not exceed 15 months from date on which machine leaves the factory.

Pre-sale services:(1) Device model choice.(2) According to customer's special requirements, design and manufacture of products.(3) Training technical personnel for clients.(4) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program.Sale services: We will send technicians to you for guiding the equipment installation and commissioning and staff training.Sales tracking :(1) product acceptance.(2) to help customers develop construction programs. After-sale services :(1) Guiding customers' installation.(2) On-site training of operators.(3) Complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

contact us

Please fill in your need products and your message and do not forget mail and/or phone if you like to be contacted.We are the professional machine manufacturer in China.

I need to ask you some details for sending you the more suitable quotation,

1.What is the raw material do you want to process?

2.What is the capacity per hour do you need?

3.What is the raw material input size?

4.What is the output size of your product?

Request for Quotation

Of course, free live-chat is available and you can get help immediately.Or you can send me email .

I hope you can tell me these details,i will give you the best quotation ASAP ,thanks.Your satisfaction is our greatest pursuit, we would like to sincerely for your service!We look forward to your inquiry!