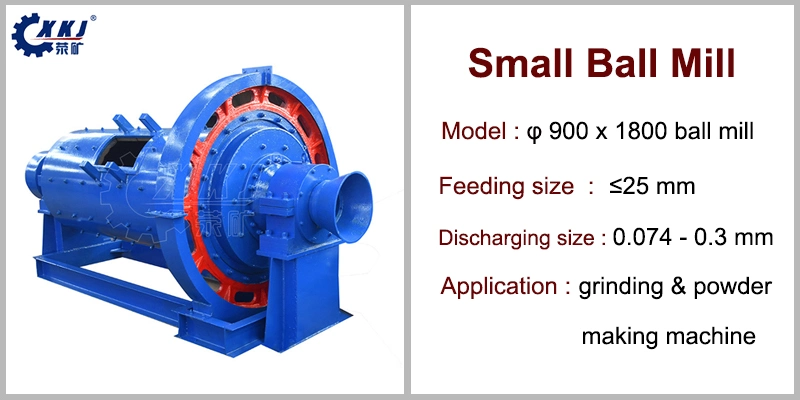

Mining Ore Iron Tin Manganese Lead Aluminum Gold Copper Powder Grinding Wet Stone Grinder Ball Mill Price

Basic Info

| Type | Ball Mill |

| Motor Type | AC Motor |

| Motor Power | 22KW |

| Rotationl Speed | 38r/Min |

| Application | Mine |

| Materials | All Kinds of Ore Grinding |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | 1 Year |

| Transport Package | Container |

| Specification | 900 |

| Trademark | XKJ |

| Origin | He Nan |

| HS Code | 8474209000 |

| Production Capacity | 2t |

Product Description

Product Description

There are two types of Ball Mills (grid type MQG / overflow type MQY), which are used for one-stage grinding and two-stage fine grinding respectively,Ball Mill is the most common grinding equipment in metallurgy and mineral processing projects. It usually adopts the edge drive mode. The materials enter into the ball mill continuously and evenly through the feeder. The motor drives the mill barrel to rotate through the reducer. The materials first enter into the mill barrel through the feeding spiral barrel. The steel ball medium and materials in the mill are subject to the friction generated by the rotary rotation of the barrel Under the action of friction and centrifugal force, the material is brought to a certain height and then dropped. Then the material is hit and ground by the grinding body. The crushed product is discharged from the mill. The qualified material is selected by the separation equipment. The unqualified material in the recycling powder system continues to return to the mill and is hit and ground by the grinding body until the fineness is qualified.

The ball mill is the key equipment for crushing the material after being broken. It applies to grind material to get designed requirement of size. Widely used in mineral processing, building materials , chemical industry and etc. It is divided into dry and wet grinding methods. According to the different ways of ore discharge, it can be divided into lattice type and overflow type.

Detailed Photos

| Model | Shell rotary speed(r/min) | Max . ball charge(t) | Input size (mm) | Output size (mm) | Capacity (t/h) | Power (kw) |

| MQG900X1800 | 38 | 1.8 | ≤25 | 0.074-0.6 | 0.8-1 | 22 |

| MQG900X3000 | 37.4 | 2.7 | ≤25 | 0.074-0.3 | 0.8 | 30 |

| MQG1200x2400 | 32 | 4.8 | ≤25 | 0.074-0.6 | 1.5-2 | 45 |

| MQG1200X4500 | 30 | 5.2 | ≤25 | 0.074-0.6 | 1.5 | 55 |

| MQG1500x4500 | 28.8 | 10 | ≤25 | 0.074-0.4 | 3-4 | 110 |

| MQG1500x5700 | 28.8 | 12 | ≤25 | 0.074-0.4 | 3-5 | 130 |

| MQG1500x6400 | 28.8 | 13 | ≤25 | 0.074-0.4 | 3-5 | 130 |

| MQG1830x5400 | 24.5 | 15 | ≤25 | 0.074-0.4 | 5-7 | 210 |

| MQG18306400 | 24.5 | 19 | ≤25 | 0.074-0.4 | 5-7 | 210 |

| MQG1830x7000 | 24.5 | 20 | ≤25 | 0.074-0.4 | 6-8 | 245 |

| MQG2200x7000 | 21.6 | 30 | ≤25 | 0.074-0.8 | 8-10 | 380 |

| MQG2200x9000 | 21.4 | 34 | ≤25 | 0.074-0.8 | 8-10 | 475 |

| MQG2400x7000 | 20.4 | 36 | ≤25 | 0.074-0.8 | 10-14 | 475 |

| MQG2400x8000 | 20.4 | 42 | ≤25 | 0.074-0.8 | 10-14 | 560 |

| MQG2600x8000 | 19.6 | 52 | ≤25 | 0.074-0.8 | 16-20 | 630 |

| MQG3000x9000 | 18.3 | 78 | ≤25 | 0.074-0.8 | 20-25 | 1000 |

Features of ball mill1) The ball mill is an efficient tool for grinding many materials into fine powder.2) Ball mill is widely used in building material, and chemical industry.3) There are two ways of grinding: the dry way and the wet way.4) Ball mill can be divided into tabular type and flowing type according to differentexpelling mine5) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.6) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.7) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

Packaging & Shipping

Henan Xingyang Mining Machinery Manufactory have five standard heavy industrial workshops covering 80,000 square meters,more than 160 machines used for gold processing,plug welding and assembling with large and medium sizes, and more than 500 works including over 50 administrators with intermediate and senior title and engineering technicians.

After Sales Service